Insulation Aluminium Coil for Efficient Thermal Management

Why Insulation Matters

In modern industry and construction, insulation is not just an add-on—it’s a necessity. From commercial buildings to complex machinery, effective thermal management ensures reduced energy consumption, enhanced safety, and improved system performance. Lightweight, corrosion-resistant, and highly reflective, aluminum plays a vital role in shielding systems from thermal loss or gain.

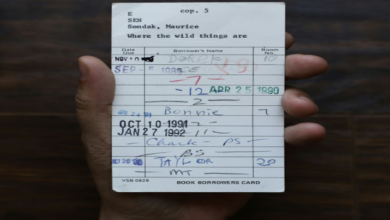

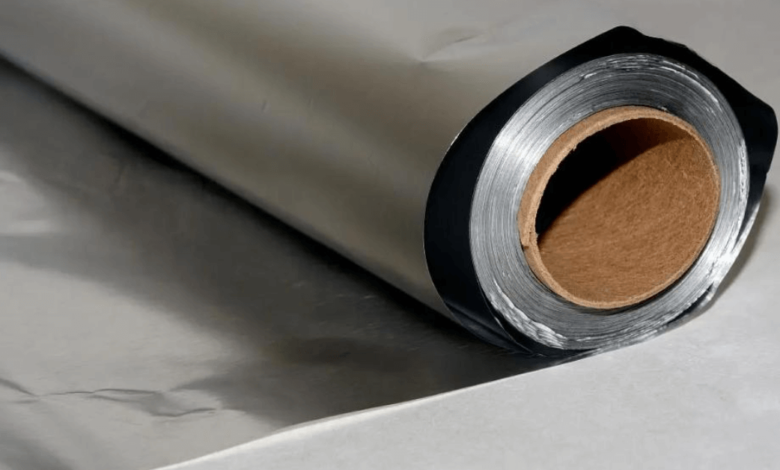

What is Insulation Aluminium Coil?

An insulation aluminium coil is a rolled aluminum sheet specifically manufactured for use in thermal and protective insulation systems. These coils are often used as jacketing over insulation materials applied to ducts, pipes, tanks, and vessels. The aluminum acts as a physical and thermal barrier, increasing the longevity and efficiency of insulation materials beneath.

Coils are available in various alloys and finishes, depending on the specific application. They may include moisture barriers like polysurlyn or kraft paper, which provide additional protection against humidity, chemicals, or physical damage.

Key Characteristics

The wide application of insulation aluminium coil is due to its exceptional set of properties:

- High thermal reflectivity: Reflects radiant heat away from the system.

- Corrosion resistance: Resistant to rust and environmental damage.

- Lightweight: Easy to handle and install, even in high-elevation settings.

- Flexible: Easily wraps around irregular shapes and contours.

- Durable: Offers long-lasting performance in demanding environments.

These properties make it a preferred material for both hot and cold insulation systems.

See also: Unlocking Bookkeeping Secrets for Business Growth Tech Trends Gfxprojectality

Where It’s Used

Industrial Plants

In facilities like chemical processing units, oil refineries, and power plants, aluminum coils are wrapped around pipework and tanks to regulate temperature and protect systems from the harsh outside environment. These facilities often experience extreme temperatures and corrosive gases, where durable jacketing becomes essential.

HVAC Systems

Heating, ventilation, and air conditioning systems benefit from insulation aluminium coil to minimize heat loss or gain through ducts. This increases energy efficiency and reduces operational costs.

Cold Chain and Refrigeration

Cold storage units, refrigerated transportation, and food processing areas all rely on precise thermal control. Aluminum coils act as a protective skin, keeping the internal temperature stable and reducing thermal leakage.

Building Insulation

In construction, insulation aluminium coils are used behind curtain walls, ceilings, and insulation boards. They provide both a physical and radiant barrier, making buildings more energy efficient and compliant with green standards.

Types of Coatings and Barriers

The coating selection depends on the environmental conditions and project requirements.

- Polysurlyn Moisture Barrier (PSMB): A high-performance plastic film bonded to the aluminum’s underside to prevent moisture intrusion.

- Kraft Paper: A more economical option that still provides basic moisture and scratch protection.

- Embossed Finish: Not a coating, but a surface pattern that increases coil rigidity and improves appearance while hiding fingerprints and minor damages.

These enhancements increase the coil’s effectiveness and lifecycle, especially in demanding environments like chemical zones or coastal areas.

Alloy and Temper Options

Insulation aluminium coils come in several alloy compositions and temper types. Popular choices include:

- 3003 Alloy: Offers good corrosion resistance and workability, often used in general-purpose insulation applications.

- 1060 Alloy: High purity aluminum with excellent corrosion resistance and thermal conductivity.

- 5005 Alloy: Slightly higher strength and better color consistency after anodizing.

The temper, such as H14 (half-hard) or H24 (quarter-hard), determines how flexible or rigid the aluminum is. Softer tempers are easier to wrap around tight curves and irregular shapes.

Installation Tips

Proper installation of insulation aluminium coil ensures maximum performance and longevity. Here are some helpful guidelines:

- Preparation: Surfaces should be clean and dry before wrapping to prevent corrosion underneath the jacketing.

- Overlap and Seal: Edges should overlap and be sealed with aluminum tape or sealant to prevent moisture entry.

- Fasteners: Use stainless steel or aluminum fasteners to prevent galvanic corrosion.

- Thermal Expansion: Leave appropriate gaps or apply tensioning techniques to accommodate expansion and contraction due to temperature changes.

Skilled installers and proper procedures are essential to avoid issues like corrosion, insulation failure, or safety hazards.

Sustainability Benefits

Aluminum is one of the most recyclable metals, maintaining its quality through repeated recycling processes. Using insulation aluminium coil aligns with green building practices and contributes to certifications like LEED or BREEAM. Its long life cycle and minimal maintenance requirements reduce the carbon footprint over time.

Moreover, the thermal efficiency offered by aluminum insulation contributes directly to lower fuel or electricity usage in climate-controlled systems.

Choosing a Supplier

Selecting a trusted insulation aluminium coil supplier is crucial for project success. Here are key criteria:

- Product Quality: Ensure the supplier provides coils that meet international standards like ASTM or EN.

- Customization Options: Look for a supplier who offers various sizes, coatings, and alloys to fit your exact needs.

- Technical Support: Good suppliers help with specification, application, and even installation advice.

Conclusion

The insulation aluminium coil is far more than a protective metal sheet—it is a high-performance component that plays a vital role in energy efficiency, environmental protection, and system durability.

Whether you’re working on a refinery, a hospital HVAC system, or a large-scale cold storage facility, choosing the right insulation aluminium coil can lead to significant energy savings and long-term reliability. Partnering with an experienced supplier will ensure you receive the right product, configured for your exact needs, and ready to perform under any conditions.