How Polystyrene Packaging Safeguards Products with Smart Customization

1. Introduction

In today’s high-speed, efficiency-driven supply chains, packaging is no longer just about containment—it’s about protection, presentation, and sustainability. Whether you’re shipping delicate electronics, automotive parts, or high-value e-commerce goods, ensuring your products arrive safely is mission-critical. This is where Polystyrene packaging steps into the spotlight.

Lightweight, cost-effective, and incredibly versatile, Polystyrene packaging is quickly becoming a preferred solution across industries. When coupled with Bespoke Foam Packaging techniques, businesses gain a competitive edge in protecting and presenting their goods during transit.

Let’s explore how this unassuming material offers advanced protection, cost savings, and custom solutions for packaging challenges in a wide variety of sectors.

2. The Science Behind Polystyrene Packaging

Expanded polystyrene (EPS) is composed of 98% air, making it incredibly lightweight yet remarkably protective. Its structure provides shock absorption, thermal insulation, and resistance to moisture and decay. At Advanced PP, this foam is transformed into high-performance packaging solutions that address specific protection requirements without the need for expensive tooling or delays in production.

Key Characteristics of Polystyrene Packaging:

- Non-toxic and chemically inert: Safe for medical and food-related applications.

- Rot-proof and moisture resistant: Ensures durability in fluctuating environments.

- Lightweight and cost-efficient: Reduces shipping costs while offering robust protection.

- Easily cut and shaped: Enables fast customization without tooling.

- Available in flame-retardant options: Suitable for high-risk environments.

See also: The Art of Bookkeeping for Small Businesses Stripcjar

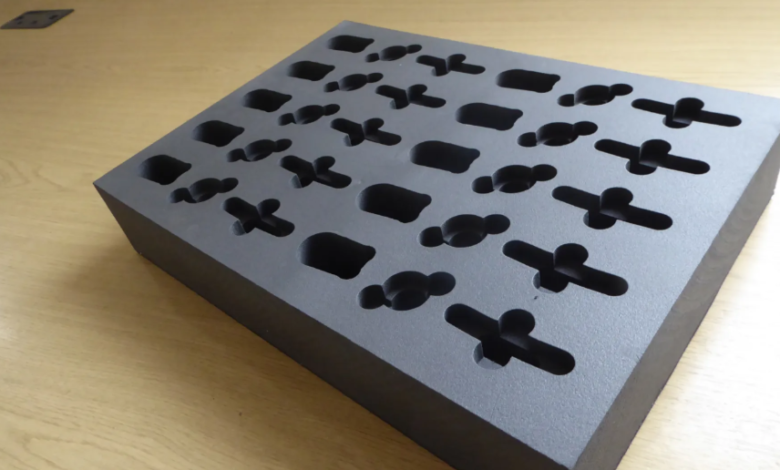

3. The Benefits of Bespoke Foam Packaging

When off-the-shelf packaging isn’t enough, Bespoke Foam Packaging offers custom-engineered solutions that perfectly cradle, support, and secure any product. Whether it’s a sensitive medical device, a fragile glass product, or a heavy-duty mechanical component, bespoke inserts provide tailored protection.

At Advanced PP, custom foam packaging includes a variety of foam types like:

- Polystyrene blocks – Ideal for rigid, impact-resistant applications.

- Polyurethane foam – Soft, cushioning support for sensitive goods.

- Plastazote and polyethylene foam – Durable yet flexible, suitable for premium items.

These are not just functional. Foam inserts also enhance unboxing experiences and reflect brand quality, especially for high-end retail or e-commerce businesses.

4. A Complete, One-Stop Packaging Solution

One of the standout benefits of working with a packaging expert like Advanced PP is the access to a complete packaging ecosystem. Beyond Polystyrene packaging, clients receive coordinated components such as:

- Corrugated boxes (single/double wall) tailored for stacking strength and branding.

- Protective tapes and pallet wraps, including branded options and those compliant with the UK Plastic Packaging Tax (30% recycled content).

- Bubble wrap and void fillers to prevent movement and cushion shocks.

This integrated approach ensures compatibility between packaging elements, reducing material waste and simplifying logistics. Instead of managing multiple vendors and mismatched components, clients enjoy efficiency and cost savings with a single-source provider.

5. Fast Turnarounds and Zero Tooling Costs

One of the unique advantages of polystyrene packaging is its flexibility in production. At Advanced PP, there’s no need for costly moulds or tooling. This means even small production runs or last-minute adjustments can be handled quickly.

The company even provides free samples and design consultation—removing barriers for businesses that want to test packaging solutions before committing. If needed, boxes or cartons are supplied alongside the foam inserts for a cohesive packaging system. In industries where speed to market is essential, such responsiveness is a game-changer.

6. The Value of Customization for Industry-Specific Needs

Every industry has its own packaging challenges. Electronics require anti-static cushioning. Medical equipment must avoid contamination. Retail needs appealing presentation. Here’s how bespoke foam packaging addresses these needs:

- Medical & Healthcare: Clean, inert, and easily sterilized polystyrene protects surgical tools and diagnostic devices.

- Automotive & Aerospace: Inserts shaped for complex geometries reduce transport damage and support just-in-time manufacturing.

- E-Commerce & Retail: Branding-friendly inserts and color-coded boxes help elevate the customer experience.

- Technology: Foam inserts protect against vibration, static discharge, and impact.

The ability to create tailored solutions for such a broad range of industries showcases the versatility of bespoke foam packaging and reinforces why businesses across Manchester and the UK choose Advanced PP.

7. Sustainability and Smarter Packaging Practices

In today’s eco-conscious market, sustainability is no longer optional. That’s why Advanced PP places emphasis on:

- Recyclable and biodegradable materials

- Minimizing excess packaging through efficient design

- Offering products with recycled content, such as stretch wrap that meets the UK’s packaging tax standards

By designing smarter packaging, businesses not only reduce environmental impact but also save on shipping costs, storage space, and handling time.

8. Client Testimonials and Real-World Impact

Customer feedback highlights the tangible benefits of using tailored polystyrene and foam packaging.

“Advanced PP have helped us reduce breakages in transit by over 90%.” — Logistics Manager, Manchester

“The packaging they created for our custom electronics was faultless. Fit, finish and protection — all spot on.” — Product Designer, Cheshire

These results aren’t accidents—they’re the product of careful design, local expertise, and decades of experience.

9. Why Choose Advanced Protective Packaging

✔ Manchester-Based Manufacturer: Local support with UK-wide service

✔ ISO-Standard Quality: Reliable, consistent packaging performance

✔ Free Design & Samples: Start faster without setup costs

✔ In-House Expertise: Creative solutions that solve complex packaging problems

✔ 30+ Years of Experience: A partner trusted by businesses large and small

By choosing Advanced PP, clients gain more than a supplier—they gain a strategic partner dedicated to product protection, brand reputation, and operational efficiency.

10. Conclusion: Polystyrene Packaging as a Strategic Advantage

In the fast-moving world of product distribution, your packaging choices directly affect customer satisfaction, cost control, and brand reputation. Polystyrene packaging, when designed and implemented correctly, offers an unmatched combination of strength, flexibility, and cost-efficiency.

Through Bespoke Foam Packaging and a holistic packaging approach, Advanced PP delivers tailored solutions that help businesses protect what matters most—from factory to final delivery.